Pt.2? More like v.2. Not to worry, I'll be finishing v.1, but as I said in the previous post, it turned out bigger than I wanted. My second attempt would be smaller.

Do you know what's hard? Well of course, comedy is hard, but that's not where I'm going. What's hard is trying to align and drill holes in a round brass tube. On the first thrower, I took care to mark and drill as accurately as possible, yet there were some small discrepancies. Now, do you know what's easy? Well of course, dying is easy, but that's not where I'm going. What's easy is aligning and drilling holes in a square brass tube. And that's what I did.

To find the center of the tube, I set my dividers by eye to what looked like half the width. Then drawing one leg along each side, I scribed two lines down the middle. I was lucky, and both lines were close enough to each other, I was able to mark the holes' locations without further adjustment. BTW, these holes locate the cross braces.

Next I needed holes to position the bow arms. I turned the tube over, marked their locations with a scribe, then scored a line across each corner with a knife-edged file. This allowed me to locate and continue filing with a round-edged file. I made certain to hold the file at a 45° angle to both adjacent sides, and proceeded until I just broke through. Then from each location, I drilled through diagonally to the opposite corner. (Pay no attention to the two holes in the middle of the side. The real holes are opposite of this side.)

Next I slide a round tube into the................Wait. Whhhaaat? You thought I was going to use square tubes for......... nooooo. No, the square tube is a jig for drilling holes in the round tube. OK, the round tube slides in until it hits the wire which blocks the jig. Next drill a hole in the top location.

To keep the tube aligned, this wire with a leg at 90° goes into the hole just drilled.

Now a hole is drilled in the bottom location.

Being careful to not let the alignment wire pop out, turn the jig over, choose one of the holes, and drill in towards the center. (Remember which location you drilled from. When you make the second upright, you'll drill from the opposite location.) This jig positions the bow arms at a 135° angle to the cross pieces.

Finally use a razor saw to cut the tube flush with the jig. This produces a 3/4" upright.

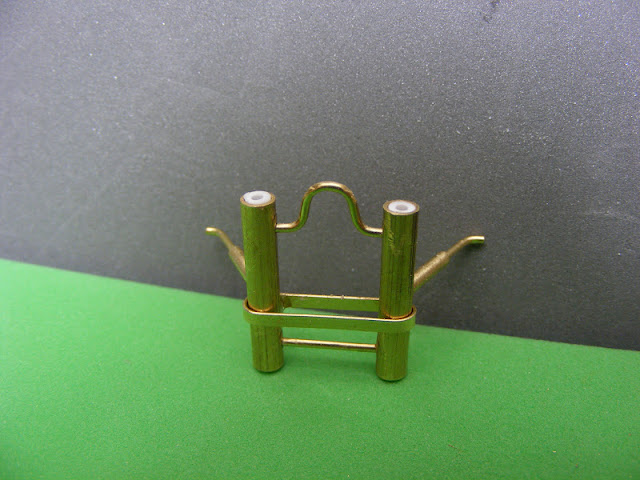

In these two shots you can see how I changed and simplified the new thrower from the original. First, the upright tubes are a smaller diameter, and seem to have something inside them. (I'll get to that in a minute.) They are also closer together, and the cross-supports are round rod instead of flat-stock. I do have some flat-stock wrapped around the uprights. This is where the bolt trough will attach. The bow arms are shorter. Now, back to what's inside the uprights. I had some plastic tube that fit perfectly, so I cut them flush and re-drilled the holes. I found the arms and cross-supports were held snugly and in perfect alignment. After the problems I had gluing the original thrower, I had at first planned on soldering this one. The plastic tube makes that step unnecessary.

I wrapped some more flat brass around the uprights, as well as completely around the bolt trough.

I made a pivot/swivel and placed it directly under the uprights, for better balance. To give me an idea of how high this thrower would sit, I placed it in the stand of the original, then set it on this proof of concept mock-up of the shooting position. Too tall. I could make a smaller base for it.

Here it is, shorter (the center post is only 3/8" tall) and a slightly different design.

Maybe I can make it a little lower.

My three ballistae side by side. The bolt trough on v.2 isn't much shorter than the original, but is certainly more delicate looking

I may play around with the location of the pivot/swivel to lower the thrower a little more, but overall, I think I have the model I want to go with on the walls. Comments and questions always welcome. Don

No comments:

Post a Comment