Has this ever happened to you? You start with a minor project, almost a throw-a-way, that you think will take an hour at most, and it GROWS and GROWS and GROWS completely out of proportion? Like this font size? Well, has it?

It's happened to me. I had a perfect little culvert ready to install in the foam. Just need to carve a little here. Y'know, since I'm carving, why not carve a little more, and I can add some wing walls. Wow, I think this needs a sluice. And a holding pool. Every new feature was an improvement, but its location on the board will make it hard to see. I kept trying to stop, "This is enough," or "You're wasting your time." But I couldn't, I just couldn't. But I'm getting closer. So let me bring you up to date on the culvert.

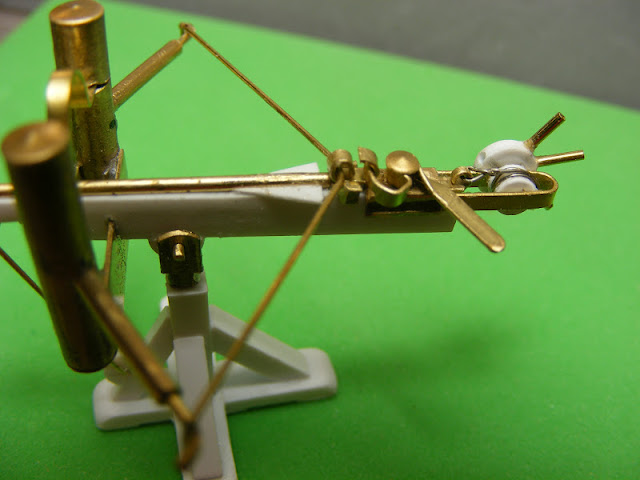

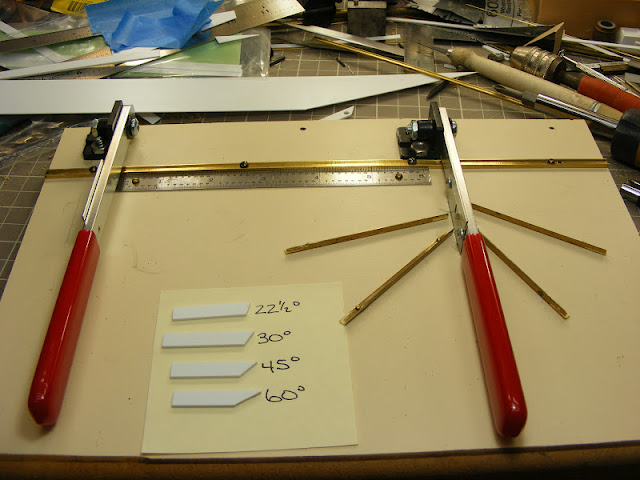

First, this is the knife I am doing all the foam cutting with.

Here you can see the procedure I forgot to take a picture of in the last installment. This is going to be a shallow ford, so I used 1/2" foam core instead of 1/4". Where the channel narrows and turns left, is where the culvert will be.

Here it is after two days. The original model was simply the face with the semi-circle, and the top cap. I had carved out for it in the foam, and planned to carve the adjoining foam to look like rock faces. Instead, I made the long and short wing walls (just the upper part).I used the remaining stone cap and some styrene strip to cap them both. Using more styrene, I made the step ledges, then added the lower walls underneath. After that came the stonework inside the arch, the angled runway, and the bottom stonework. At some point during all this, the corner stones with the beveled tops appeared, as well as the plain styrene sheet on the very bottom.

At this point the plan was to have the foam rocks right against the outside of the wing walls. However, if I held the rock walls back, I could detail the outsides of the wings. Here also the plan was to have the bottom curved styrene sit flat on the foam, and carve the creek channel away from it. I would cover the styrene with sand and small stones.

To protect the top of the culvert, I fitted a piece of Plastruct's Polished Stone to it.

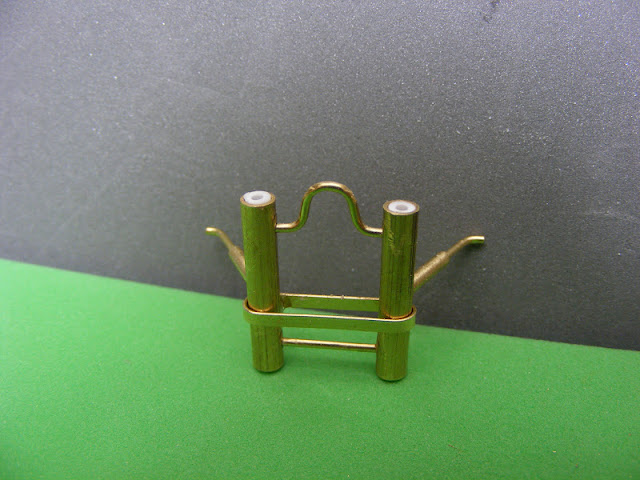

Gotta have bars. These are 3/64" brass rod.

I had the Polished Stone out anyway, why not use a little more? I covered the bottom styrene sheet, put some spacer strips underneath, and attached a piece that would be the creek bed.

Another view of the top. The rear edge of the stone would sit next to the wall.

Okay, every time I made an addition, I had to carve out more foam so it would fit. At this point, the culvert was a hair thicker than the 2" of pink foam, so I cut all the way through, put a piece of 1" Styrofoam underneath, then carved another 1/2" into it. Now my terrain boards are 3" thick, which really doesn't bother me too much. It adds a lot of stiffness (flatness), plus gives me more lee-way in my carving. Speaking of carving, my attempts to carve and fit rock faces into the spaces here in place were becoming very frustrating. Alright, I would remove the culvert, carve and add the rocks to it at the bench, cut out a bigger hole for it in the boards, then fill in with Sculptamold around the whole she-bang. Which is what I started to do................when I remembered those Woodland Scenics rubber rock-molds I had stashed.

New Plan! The molds were designed with plaster in mind, but I had a little resin left from the buttress project that I knew would be going bad soon, so I mixed it up and poured it in. This left me with plenty of rocks to play around with. I came up with the arrangement you see in the next couple of pictures.

Next I used Woodland Scenics Flex Paste and Foam Putty to fill in the gaps between the rocks. I finished the first coat late last night, and left them to dry. Left them to dry? Geez, where have I heard that before?

I feel like I'm getting the upper hand on this bastard, and hope to be getting it done soon. I know, I know, "Famous last words." Next time, there will be water. Don