I began by laying one of the craft on a piece of graph paper, and tracing around the entire waterline. Then I traced around the front half of the waterline, finishing the back with a loop.

I ended up with this. The slots will 'capture' the wire portion of the ramp hinge.Transfer these shapes to some .040 styrene, and cut them out, leaving the slots for later.

The front of the landing craft has a slight curve. Take a file and remove it, leaving a nice, flat edge.

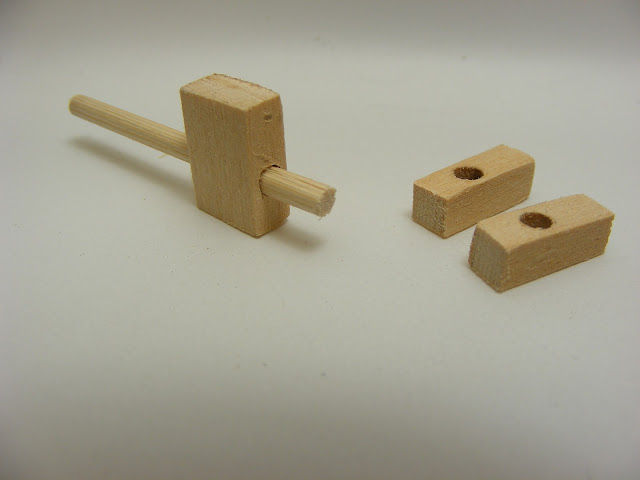

Take a grinding wheel, and flatten about a one inch section of 1/16th brass tube. (Don't sweat it if you don't have a Dremel Tool, the file in the above picture will work as well, if a little slower.)

Using a razor saw, cut the tube to 3/4 of an inch.

Join the two flattened edges with CA. The tube should be flush with the inner side of the ramp.

Take a three inch piece of 3/64th brass rod, and make as sharp a 90º bend as you can at the one inch mark. Make a very slight bend about 3/8ths inch from the corner on the long leg, then slide the long leg through the tube. (That slight bend will create enough friction to hold the ramp in the position you place it.)

Make another tight 90º bend , then trim the legs to 3/4 of an inch. You will need to hold the tube with a pair of flat-jawed pliers while you make the bend, or you'll risk breaking the glue bond. Even using the pliers, and exercising extreme caution, I still broke loose one on the tubes. Be careful you do not glue the rod to the tube when you re-attach it to the ramp. When done, the legs should fit the slots. If not, adjust the slots to the legs

The slots now cut out of the styrene. Before attaching it, lay a piece of 150 grit sandpaper on a flat surface ( a piece of glass is perfect), then sand the bottom of the LCVP, removing any surface imperfections, and leaving it perfectly flat. The coarseness of the grit should leave some score lines, which will help the adhesion. Run a bead of thickened CA around the perimeter of the bottom, then attach the styrene, giving it a slight wiggle as you match the edges. Don't worry about a little squeeze out, it is actually desirable. I usually use an accelerator at this time, or you can just wait for the CA to set.

Now use the CA to glue the legs into the slots. Keep the glue 1/8th of an inch away from the tube, and you'll have no worries.

Using some thickened styrene cement (I like Testor's/Model Master's with the metal applicator), apply generous amounts where the small bottom piece will fit, then attach it, again using the 'wiggle' technique. Don't worry about a little squeeze out here, either.

Using needle files and sandpaper, trim the styrene flush with the sides of the model. The squeeze out should have reduced any voids in the seam line, reducing the need for putty. Try to blend the back curve of the small piece into the larger. No need to go crazy here, it is not noticeable when the LCVP is 'floating upright.'

The styrene sanded flush with the sides.

Primed, and with a coat of Tamiya's Medium Blue.

Two of the crew installed, and the ramp down. Compare this shot with the one above. Notice how different backgrounds and lighting can make the model seem to be two different colors.

Just for comparison's sake, while making the BattleFront craft, I bought one from Peter Pig, and one from Quality Casting (I think). Not sure which is which. The top one is similar in width to the BF offering, but sits much lower. The bottom one sits higher, but is too narrow to fit a small BF base.

The assault troops on two small bases...........

.....................and in their crafts. The colors in these two shots are closest to the actual models.

Heading for shore. The 'ocean' is a reusable furnace filter. The top shot was done with flash, the bottom natural light.

I hope you all enjoyed this project. If any are sitting on the fence about this box set by BattleFront, get down and order it now. You will not be disappointed. Who knows if they will re-issue it again. Don

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)